REFRACTORY CATALOGUE

Refractory materials are resistant to decomposition by heat, pressure, or chemical attack, retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, inorganic, non-metallic, porous, and heterogenous. They are typically composed of oxides or carbides, nitrides etc. of the following materials: silicon, aluminium, magnesium, calcium, boron, chromium and zirconium.

Refractory materials are used in furnaces, kilns, incinerators, and reactors. Refractories are also used to make crucibles and moulds for casting glass and metals and for surfacing flame deflector systems for rocket launch structures. Today, the iron and steel industry and metal casting sectors use approximately 70% of all refractories produced.

OREX MINING COMPANY DMCC was established in the year 2014 as a free zone entity registered in DMCC free zone, Dubai, United Arab Emirates.

The refractory division of Orex Mining Company DMCC has entered a joint venture with m/s Benxi Weir High Temperature Materials Co. Ltd., Benxi, China to act as a sole distributor partner for refractory products in India and the Middle East.

Benxi Weir High temperature Materials Co. Ltd. Is situated on the beautiful mountains of Benxi. This has abundant availability of raw materials especially magnesite mines which is the major component for refractories. The company has two manufacturing facilities of 18,000 and 32,000 MTPA of refractory bricks and gunning material along with other refractory products. The nearest port for shipment is the post of Dalian which is around 380km away from the company.

Our company has Limestone and Pyroxenite Mining operations in the Fujairah region of UAE. We are exporting low silica limestone and high grade pyroxenite to integrated steel plants in India, Limestone to Bangladesh and Kuwait for cement plants.

OUR CERTIFICATIONS

Ladle for Furnace

Ladle Materials

Electric Arc Furnace

Electric Arc Furnace Materials

Taphole Block for EBT

Refractory Tundish

Tundish Materials

Working Lining for Ladle

Properties of MgO-C Bricks

Properties of Carbon-free AI2O3-Mgo Bricks

MgO - C Brick for Lining Furnace

Properties of MgO-C Bricks for Lining Furnace

Properties of EAF Roofs

Properties of Refined Furnace Roof

Tundish Specification

Properties of Coating Mix for Tundish

Properties of Dry Vibration Mix for Tundish

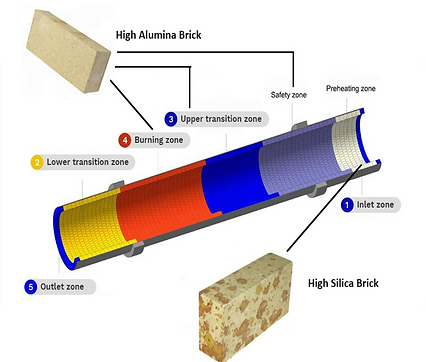

Refractory Lining for Rotary Kiln and Shaft Kiln

Refractory Lining

The purpose of the refractory lining is to insulate the steel shell from the high temperatures inside the kiln, and to protect it from the corrosive properties of the process material. It may consist of refractory bricks or cast refractory concrete, or may be absent in zones of the kiln that are below approximately 250 °C. The refractory selected depends upon the temperature inside the kiln and the chemical nature of the material being processed. In some processes, such as cement, the refractory life is prolonged by maintaining a coating of the processed material on the refractory surface. The thickness of the lining is generally in the range 80 to 300 mm. A typical refractory will be capable of maintaining a temperature drop of 1000 °C or more between its hot and cold faces. The shell temperature needs to be maintained below around 350 °C to protect the steel from damage, and continuous infrared scanners are used to give early warning of "hot-spots" indicative of refractory failure.

Basic Components of Rotary Kiln

1.SHELL

2.REFRACTORY LINING

3.SUPPORT TYRES (riding rings)

4.ROLLERS

5.DRIVE GEAR

6.INTERNAL HEAT EXCHANGES

Different Zones of Rotary Kiln

LOWER TRANSITION (HIGH ALUMINA BRICKS)

Temperature in this area comes down from 1510℃ to 1300℃. This is another very critical area of the kiln which is subjected to tremendous abrasion from clinker balls and also axial thrust at the retainer area.

BURNING ZONE (HIGH ALUMINA BRICKS)

The final stage of clinker compound formation occurs in this zone where some of the reactions are exothermic. Temperature in this zone varies from 1400℃ to 1510℃. Clinker liquid phase is predominantly present in this area and the kiln lining is under coating. Most important property for refractory in this area is coating friendliness, which indicates the ease with which the coating can form on its surface and stick on it.

CALCINING ZONE (HIGH ALUMINA BRICKS)

This is the zone within the kiln system where the raw materials undergo calcination. Temperature in this zone varies from 800℃ to 1200℃ . Here CaCO3 (calcium carbonate) gets converted into free lime and CO2 (carbon-dioxide) is driven off.

PREHEATING ZONE/ INLET ZONE (HIGH ALUMINA BRICKS)

The first reaction zone of rotary kiln system is known as the preheating zone. Here the charge gets heated up to about 800℃ before entering the calcining zone. Bricks in this area are prone to chemical attack from gases containing alkali and sulphur. Thermal insulating property of the refractories in this area results in substantial fuel savings.

Specifications

THE DIAGRAM REPRESENTS THE LIME IN SHAFT KILN

Standard Rotary Kiln Brick Shapes

Type of Brick for Rotary Kiln

Type of Brick for Shaft Kiln

Quicklime Kiln ( Calcium Oxide)

Calcium oxide (formula: CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term lime connotes calcium-containing inorganic compounds, in which carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominate. By contrast, quicklime specifically applies to the single compound calcium oxide. Calcium oxide that survives processing without reacting in building products, such as cement, is called free lime.

Quicklime has a wide range of uses, including in the production of iron and steel, paper and pulp production, treatment of water and flue gases and in the mining industry.